Steel Structure for Civil Engineering

Only strict self-management can protect the value of spec products.

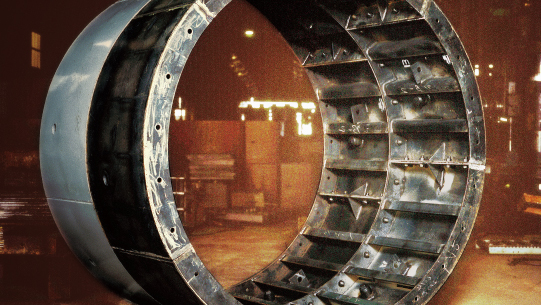

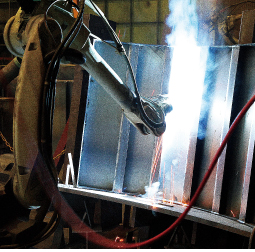

Steel segments

The most common way to construct sewage, electricity and communications tunnels is to use the shield method, whereby a tunnel-boring machine pushes forward underground like a mole. Steel segments are produced separately (in segments), and are assembled in rings within the tunnel to be used as covering material in the shield method. Therefore, the assembled segments must be highly watertight, and also able to endure stresses such as soil and water pressure.

As a plant certified by the Japan Sewage Works Association, we employ automating welding by using robots to produce uniform, high-quality products.

Tunnel support

Arch-shaped tunnel supports are installed as supports to secure underground space while the tunnel is being bored, and must be strong enough to resist pressure from the surrounding soil. Therefore, precise rounding is crucial, and we are able to utilize our bending technology, accumulated over many years, in our manufacturing in the pursuit of perfection.

Copyright (C) 2010 IZUMI STEEL WORKS,LTD.