Steel Structure

Izumi’s technology is utilized here as well.

Staying true to the basics

The difficulty in manufacturing Liquefied gas carrier tanks lies in realizing high-quality, precision production using thick plates of 600-800MPa-class high-tensile steel. We keep a close eye on the various stages of processing, assembly, and welding, which are constantly in a cause-and-effect relationship, and have all employees participate in quality control, centered on the quality assurance department. In other words, staying true to the basic principles of fabrication opened the way for us to build precision steel structures.

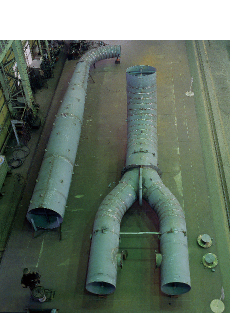

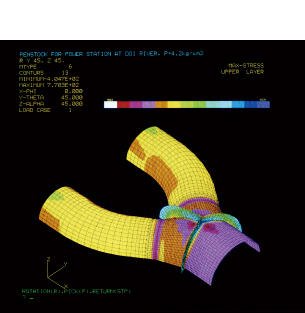

Utilizing large-scale facilities

Our tank manufacturing facilities, including a 2,000-ton press, large bending machine, and big assembly plant with 150-200-ton overhead crane, can also be used to produce large steel structures.

Copyright (C) 2010 IZUMI STEEL WORKS,LTD.